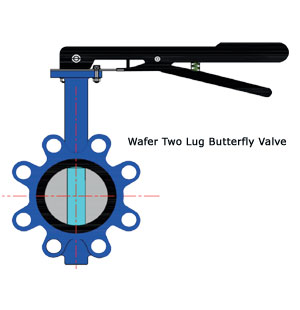

BUTTERFLY VALVES

D Valve engineers are engaged in design and manufacturing Butterfly valves in pipeline flow control. We developed wafer, lugged and Double Flanged Butterfly valves with extensive application, design and manufacturing expertise. These products are produced by employing modern manufacturing practices under a robust quality assurance system. These practices ensure consistent product quality and dependable performance. Our Butterfly valves can be operated manually, pneumatically or electronically.

Rubber lined butterfly valve is a kind of valve with thick polymer lining on the body and disc. The lining makes the body completely isolate from medium and provides excellent anti-corrosive performance. It is designed as a device to shut-off or regulate the working medium flow and installed in pipelines or vessels with medium of acid, salt and oxidant, reducing agent Or solvent in chemical, petroleum, pharmacy, food, iron and steel smelting, paper and Pulp, water power plant etc. it can be served, globe valves as well as other shutting off or regulating valves.