TRUNNION MOUNTED BALL VALVES

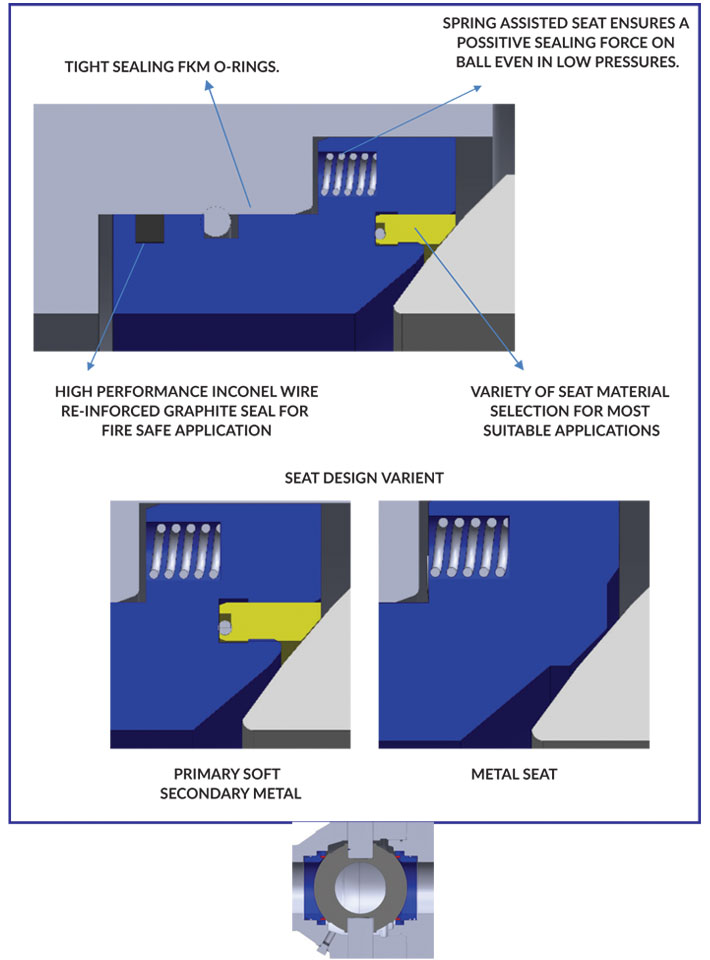

D Valve manufacturers TMBV with Combination of Soft Seat, Soft and Metal Seat and Metal Seat Ball Valves Sizes NPS 2” - 12” (DN50 to DN300) up to class 2500# with various end connections. The valves are offered in a combination of size, pressure class, material of construction, End-Connection, etc., to suit myriad applications in process plants, Oil and Gas, utility lines and HVAC. Two Piece and Three piece TRUNNION MOUNTED Ball Valves are available.