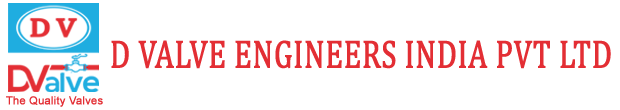

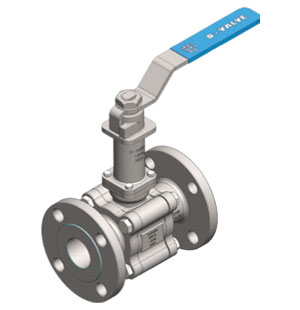

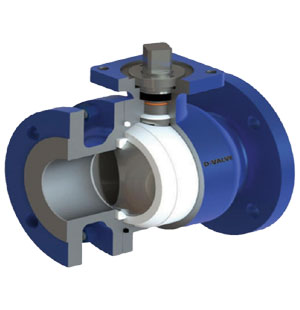

3-PIECE FLOATING BALL VALVES

D Valve 3-piece construction floating Ball valves are designed, manufactured and tested as per international standards. The quality is ensured from the receipt of components till the dispatch of the valve to the customer. Its robust design and simple construction guarantee a long working life and low maintenance. The internals of our entire 3-Piece socket/threaded end ball valves of Class 800# can be replaced without removing the valves from the pipeline. This reduces the maintenance time. All our three-piece floating ball valves are offed with manual hand lever/wrench operated by the standard. Any kind of operation mechanism like Electric/Pneumatic/Hydraulic actuators can be offered upon request to meet customer requirements.