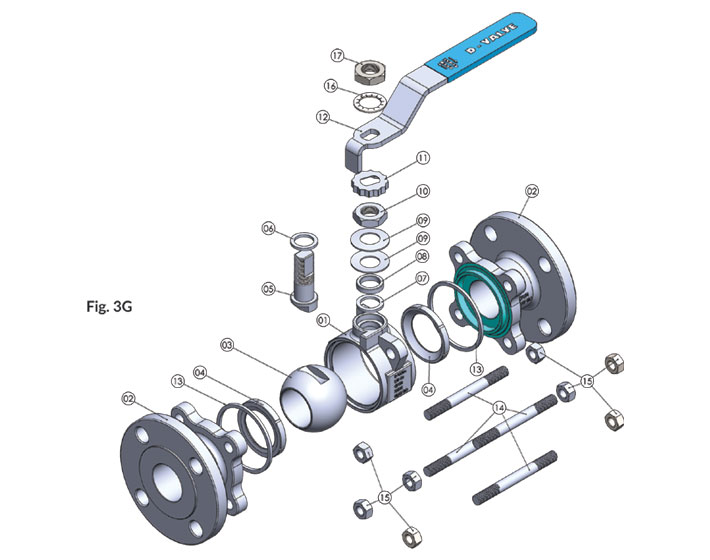

BALL VALVES

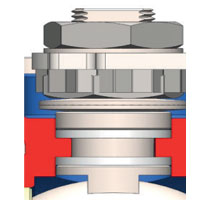

D-Valve Engineer’s ball valves are completely in-house designed, manufactured; quality and pressure tested meeting international standards such as ASME, API, ISO etc. Our Customers have the choice to select Single piece or Two piece or Three piece construction in Floating design and Two piece or Three piece in Trunnion Mounted design based on their application. Our ball valve pressure ranges are from Class 150# to Class 2500#. We offer our customers a wide selection of materials for Body/Cover, Ball, Stem, Soft and Metal seats, and Seals for the right application.

| Design Variants | |||

| Design | Floating Ball Valve |

Pressure Rating |

Class 150# - Class 2500# |

Trunnion Mounted Ball Valve – Side Entry |

Flow Bore |

Full Bore (FB) |

|

Construction |

Three Piece |

Reduced Bore (RB) |

|

Two Piece |

Seat Type |

Soft Seat and Cavity Filler Soft Seat |

|

Single Piece |

Metal Seat |

||

End Connection |

Flange End (FF, RF, RTJ) |

|

|

Butt Weld |

|||

Socket Weld |

|||

Threaded (NPT, BSPT, BSPP) |

|||