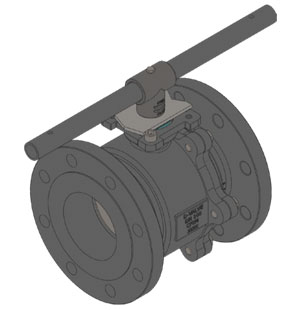

TWO PIECE BALL VALVES

D Valve in-house designed, manufactured and tested two piece ball valves are complying with international design standards such as ASME B 16.34, API 6D, and ISO 17292. These valves are designed to meet the most stringent operation requirements and ensured quality and reliability throughout the life cycle. We understand the pain of customers on maintenance of components/valves; these valves are designed and assembled with few components hence less maintenance is required in service life. We assure you our product range meets most of the customer requirements w.r.t size, pressure class, the material of construction, and design.