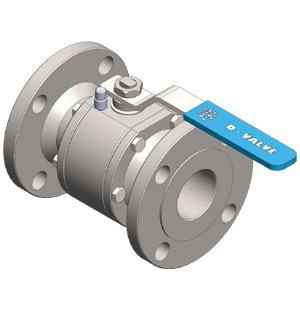

HIGH PRESSURE BALL VALVES

The main challenge in design and manufacturing of floating ball valves are to use them for high pressure application. D Valves takes that challenge and our in-house facility is capable to design and manufacture floating ball valves for high pressure application up to ASME Class 2500#. Considering application stringency, this series of ball valves are very rigid in construction and manufacture from forging or round bars. Due to the application limitation, D-valves restricted the design of high pressure floating ball valves up to NPS 4” (DN 100). The High pressure floating ball valve portfolio includes a diverse range of standard and customized valves that can be configured to suit most process applications or project packages. There are soft seated designs that provide superior sealing; metal-seated valves that maintain tight shut-off and valves designed to maintain the performance of your processes from elevated temperatures to cryogenic.